Just a reminder that I’m playing tonight at BEEP, at the Verdict in Brighton. Spooky theme! I’ll be playing some new material so come along. Lots of other great acts too, including my friends MSVFCK. https://www.facebook.com/events/178886762476440/

News

Work in progress Glitch Delay

So I’ve been beavering away on a new Eurorack effect based on the Teensy board again!

Added a very rough demo, which starts with a dry loop, then entirely wet glitch effect. Dials from top to bottom are

- Glitch window size

- Glitch window speed

- Feedback

- Dry/Wet mix

The effect is sort of a cross between my previous AudioFreeze project and a digital delay. Is consists of a delay line with a write head and a read head. The difference being the read head is basically looping a tiny buffer behind the write head. This is implemented using 2 read heads which crossfade between each other to avoid popping. The window (the size of which is controlled by pot 1) moves (forwards only currently due to lack of buffer size) through the buffer at a speed controlled by pot 2. There’s a certain element of randomness added too each time the loop restarts. It then has to jump over the write head as it cycles through the buffer.

Next stage is to extend the buffer time by adding more memory chips to my Teensy based board. I should hopefully be able to extend the time time from ~0.5s to around ~7s. This should give a lot more time to hear glitches repeat before the write head loops back around and the play heads have to skip over it.

https://github.com/cutlasses/GlitchDelay

Fort Process 2016

Yesterday I attended Fort Process festival, which took place at Newhaven Fort. It was a pretty incredible day. The fort itself, which was built in the 1860s, is a pretty amazing space to begin with. It teems with bunkers and tunnels, as well as underground chambers and gun emplacements. As you explored the fort, you continually unearthed new installations and performances. All of these were enriched by the the unorthodox surroundings, and many incorporated the acoustics of the space into the performance. I went armed with my field recorder and camera so was able to capture some of it. Some pictures below, click to see full size images. I have some nice recordings of a clicking electric fence, and some streamer tape flapping in the wind, as well as some recordings which highlight the peculiar reverb of the tunnels, I’m sure some of these will find their way into a Cutlasses composition at some point.

So much great stuff to see and hear. I really can’t think of anything else I’ve been to that’s comparable. So many great artists, but with so much stuff happening at the same time it was impossible to see it all. I’m really hoping it happens again next year. I always find events like this inspiring, and am now itching to work on some new material. Hoping to finish work on an album by the end of the year.

Static from TVs turning on and off triggered bells to ring

Inwards and co manipulate audio from other sets, live through modular setups

One of the many, very narrow, corridors. A lot of them were originally used to provide lighting behind glass windows to other rooms. As the lighting would have been gas-based, these needed to be kept out of rooms containing gun powder, so the light were in the corridors.

Live projections from Sculpture

The fort

Box of miscellaneous items and contact mics, being rumagged and generating triggers for the Nord Drum.

John Chantler

Live projections – ink was ‘marbled ‘ on oil over a light box, then super-imposed over manipulated video of the artists.

These cellos were feeding back off each other. The sound was vibrating the body of the cello using a built in speaker, which resonated the strings. This was picked up and fed back into the other cello’s body. The resulting audio was processed by software written in Super Collider, sounded IMMENSE AudioFreeze wins!

I’m really pleased to say that my AudioFreeze module has won the Music Hackspace DIY instrument competition. I didn’t build it to enter the competition, it just so happened to be running at a similar time, but I’m super pleased to have won, especially as the other entrants were pretty cool.

Got to start thinking of what to work on next. I’ve got a few of the boards left, so it will probably be based around Teensy and Audio Shield again. I’ve start using Audio Mulch to experiment with some ideas for a signal chain. Will update when things start to come together.

Build your own AudioFreeze

I’ve added the Gerber files to GitHub so anyone can build the module if they like. As a disclaimer this module should be seen as a prototype. IT HAS NO POWER FILTERING OR SHORT CIRCUIT PREVENTION, if you plug the ribbon cable in the wrong way you may damage the board and potentially your other modules. Also your case must supply 5V power (some don’t). As this was my first PCB I wanted to make it as simple as possible. I’m merely making it available as a resource for people who want to make their own boards. If you do build your own I’d love to see it. Please tweet me @scolar any pictures or videos!

AudioFreeze demo

Finally got around to putting together a little video of the AudioFreeze in action, now with 8-bit option for longer loops. Updated source code is available here

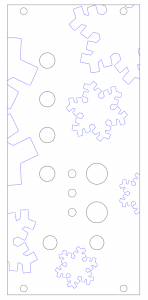

AudioFreeze Fascia complete

To be able to mount my AudioFreeze PCB in a modular case I needed to craft a fascia. I decided to use laser-cut acrylic. I haven’t found anywhere in the UK that does bespoke Aluminium cutting, and, due to a kind friend, I had access to a laser cutter! I created a vector image in InkScape, a free, well-featured vector art package. It does have its drawbacks though, it’s not particular user friendly. I haven’t found an easy way to show the centre of objects, so I ended up making guidelines to show me, and hiding them in another layer.

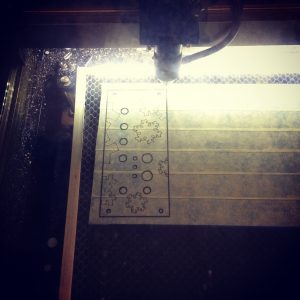

I came up with a design involving snowflakes, and I wanted these to be in a different colour. I covered the acrylic in masking tape, and once it was cut I painted over the top with several layers of thin acrylic paint. It wasn’t entirely successful, the paint didn’t fill the etched areas quite as well as I’d hope, but I’m still very pleased with the final result. One downside of using acrylic is that it’s 3mm thick, which seemed slightly too deep to be able to get a nut on the jack sockets as not enough of the barrel protruded. The Aluminium panels from the Thonk – Music Thing kits I’ve built were thin enough not to have this problem.

I’ll make another demo video soon..

Vector image for laser cutting

Laser cutting the masking taped acrylic

Painting onto the fascia

Finished article! AudioFreeze Prototype built

After a few hours of soldering my PCB is populated and it works! There was no way of knowing for sure without building it, and as this was my first PCB I had some doubts, but thankfully it’s all good. The LEDs and corresponding resistors have yet to be added, I wanted to wait for the facia before soldering these in place to get the height right It can be powered either via USB or from the 5V line on the Eurorack connection.

First version of the firmware is up on GitHub. Current version has only one mode. Top red button captures a loop of audio. Pots from top to bottom control:-

- loop window size

- loop window position

- pitch

- mix with incoming audio

Bottom red bottom currently doesn’t do anything, but my plan for the next version of the firmware is to have multiple modes. I’m thinking of a mode which has a volume based threshold for triggering the sampling, and possibly a granular delay mode. Also the ability to sample in 8 bit (rather than 16 bit) for increased loop time. LEDs are also unused currently, they will probably show active modes.

Next up is the fascia, hopefully laser cutting that this week so expect pictures soon.

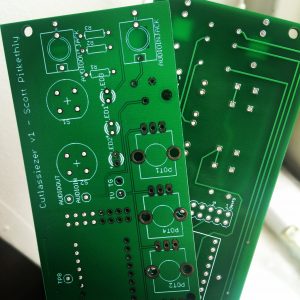

PCBs have arrived!

My first ever PCBs have arrived, possibly the first of many? Can’t wait to get the first one soldered up. After that I need to design the Eurorack panel, current plan is laser cut acrylic. Will post demos as soon as it’s made! Thanks to Hackvana for fabricating them, a highly recommended service!

Bank Holiday Making

I made the most of this Bank Holiday weekend by making up some contact mics. I’ve used mini-jacks so I can use them with my Mikrophonie module, and soldered the shielded cable directly onto the wires that come attached to the Piezo discs. I’ve dipped them in Plasti-Dip, a weird gloopy coating, that should mean they are now waterproof (hydrophones?). I had to dip each one about 4 times to get a decent amount of coating, hopefully that hasn’t deadend the sound too much. Expect videos of me freezing them in ice and recording them de-frosting (the sound designers equivalent of watching paint dry?)